Slide 45 of 250

Notes:

When all variation in a system is due to common causes, the result is a stable system said to be in statistical control. The practical value of having a stable system is that the process output is predictable within a range or band. For example, if a stable order entry system handles 30 to 60 orders a day, it will rarely slip to fewer than 30 or rise to more than 60.

Special (Assignable) Causes

If some variation is due to special causes, the system is said to be unstable since you cannot predict when the next special cause will strike and, therefore, cannot predict the range of variation. If a system is unstable and subject to special cause variation, its capability might sporadically (and unpredictably) drop sharply below or rise sharply.

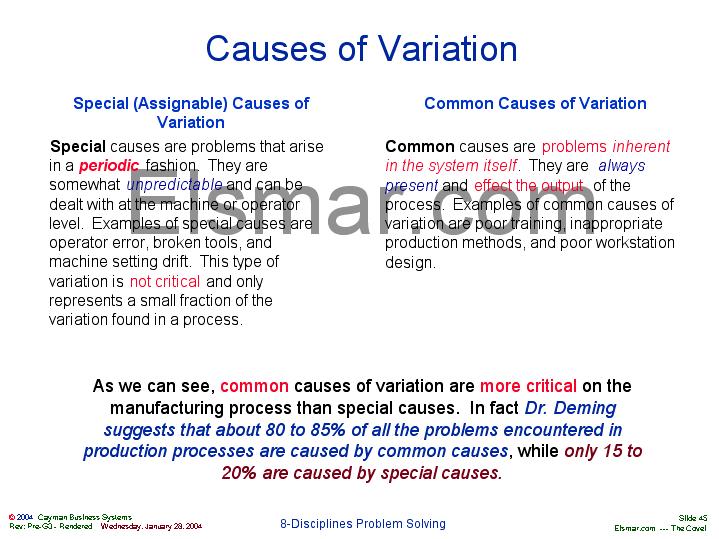

Causes of Variation

Special (Assignable) Causes of Variation

Special causes are problems that arise in a periodic fashion.� They are somewhat unpredictable and can be dealt with at the machine or operator level.� Examples of special causes are operator error, broken tools, and machine setting drift.� This type of variation is not critical and only represents a small fraction of the variation found in a process.

Common causes are problems inherent in the system itself.� They are always present and effect the output of the process.� Examples of common causes of variation are poor training, inappropriate production methods, and poor workstation design.

As we can see, common causes of variation are more critical on the manufacturing process than special causes.� In fact Dr. Deming suggests that about 80 to 85% of all the problems encountered in production processes are caused by common causes, while only 15 to 20% are caused by special causes.

ADVERTISEMENT

.

.