|

|

|        |

Slide 91 of 262

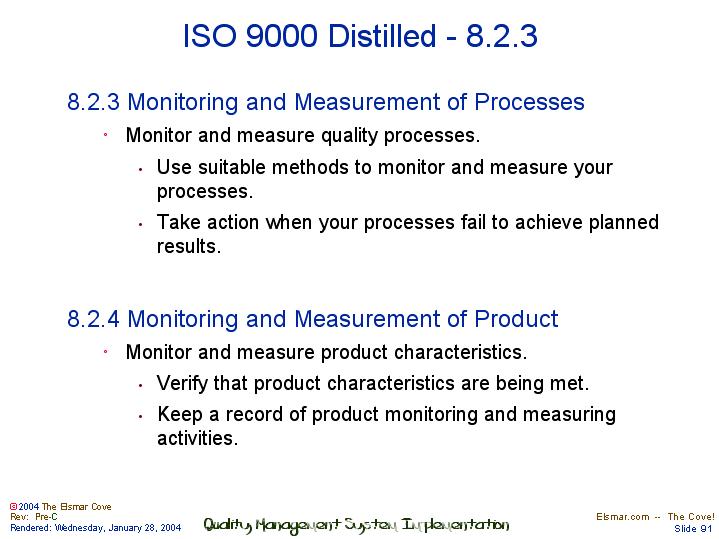

8.2.3 Monitoring and Measurement of Processes

8.2.3 is closely tied with 8.2.4 Measurement and monitoring of product. Keep in mind the product requirement and how it relates to this discussion.

Element 8.2.3 states that your company must apply suitable methods for measurement and monitoring of those processes specific to your company that allow you to deliver your product to your customer/s (realization processes). The standard states that these methods must confirm the continuing ability of each of these processes to satisfy its intended purpose. This requirement is similar to that of 4.20 Statistical Processes and also 4.9 Process Control, of the old standard.

The ISO 9001:2000 standard now has more emphasis on measuring product quality (we'll get into this more with element 8.2.4) and the processes that relate to product quality. In the past, there has been some criticism that a company could create an ISO system that would still allow you to ship bad product ‘consistently’. According to the new standard, companies will have to measure and prove the continued ability of their processes to meet their customers' requirements for the use of the product or service. The methods of measurement must be defined. A documented procedure as part of Process Control will have to define or reference the customer requirements, the intended purpose of the process, the measures of its continued ability and method of assurance, such as a review. How you react to these requirements will be greatly determined by the industry you are in and the regulations that you must follow.

The creation of a product occurs through the operation of one or more processes. You have to make sure that the processes are set up to meet customer requirements (i.e. capability studies). You continually monitor these processes (i.e. SPC) and make sure they are always set for meeting customer requirements. At the same time you use the data you are collecting to look for opportunities for improvement.

By measuring the process (for feed, speed, rate, temperature, etc.) you are utilizing the best method for helping to prevent defects your products may have. By waiting to measure a product once it has been produced, you can still prevent defects from getting to the customer, but it may too little too late. Ensuring quality in your processes goes to say that you are on the right track to ensuring quality in your products. You have to control your processes in order to produce a product that is in control.

One critical point of the new standard is the monitoring component. When one "monitors" a process, one must compare the collective variance from one set of measurements to the next, or a series of measurements, and not just make measurements and let the data sit unanalyzed. I've heard of this requirement being missed in the old standard, with measurement data being taken for ISO reasons, but not actually used as a tool for improvement (or at least used to its full extent).

The new standard is somewhat more clear on how this data must be used. A new requirement of the standard is that processes measure and show the continual ability to satisfy customer requirements (monitoring is an obvious component in identifying this). Action will have to be initiated when processes fail to satisfy requirements. Process capability must be part of the company's stated overall and specific objectives for quality. Such objectives could be included as part of the Quality Policy, measured as part of Management Review and followed-up according to Corrective and Preventive Action.

Potential Audit Questions:

1. How does your company identify which processes are critical to product realization. Describe the criteria for identifying these processes.

2. What methods are used to measure processes? Who is responsible for defining and conducting these measurements in your company?

3. What measures will you use to confirm the continuing ability for your processes to satisfy their intended purpose? Please describe.

ADVERTISEMENT

View the Elsmar Cove Privacy Policy and Terms and Conditions