Standing Tall When Dance Pushes You Down

by Stacy West

Have you ever had a teacher or choreographer who said or did something that made you feel bad about yourself or your dancing?

If you are a serious dancer the chances are good that you have. If not, unfortunately the chances are good that you may someday find yourself in that situation.

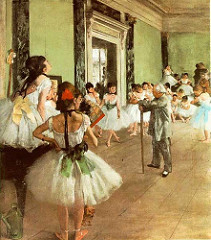

Dance teachers and choreographers have long been portrayed as authoritarian figures. There’s an almost romantic notion that you aren’t a real dancer unless you’ve experienced things like bloody feet and being screamed at by a semi-unstable teacher or choreographer. Movies such as Black Swan and reality shows like Dance Moms perpetuate this idea.

While it’s true that there are standard expectations of discipline and etiquette in dance, it’s also true that some teachers and choreographers cross the line, creating an abusive environment for their dancers.

In a world where corrections are considered a compliment, it can sometimes be confusing to tell the difference between someone who is pushing you to be your best and someone who is causing damage to you, your self-esteem and your love for dance.

Being pushed by a teacher is one of the ways you can improve. But abusive teachers gain self-esteem through the humiliation or shaming of others and they regularly use their position of authority in negative ways.

What should you do if the authority figure in the room routinely creates an environment that goes beyond the norm? As a dancer do you have the right to stand up or yourself?

The answer is a definite YES! Here are some suggestions for how to deal with the situation:

- Take a Deep Breath

Remind yourself that personal attacks which are emotionally abusive are unjustified and that you have the right to stand up for yourself. Make the decision that you will take a calm, professional approach to solving issues that have arisen.

- Read the situation

Some choreographers take their personal frustrations, insecurities and creative blocks out on their dancers. Observe the room to determine how your peers are feeling and what the root of the tension is. Discovering this can sometimes make verbal attacks feel less personal.

- Ask for Clarity

Often when situations become tense it’s because something isn’t clear. Calmly and politely explain that you are trying to give what they want but you need more clarification. Others in the room likely need it too.

- Seek the Advice of a Mentor

A mentor is someone who you trust and respect and who has a lot more experience than you do. It’s always good to have a mentor or two in your life. Use them as a sounding board when you need advice. Talk with them about your specific situation and seek their feedback on how to best handle it.

- Express Your Concerns

Make an appointment outside of rehearsal to express your concerns professionally and in person. This shows you have respect for the process. You can talk with the superior of the teacher or choreographer you are struggling with or you can talk with the person directly.

If you choose the latter, consider having a studio owner or artistic director present. If possible document your concerns in writing or an email. That way, if you need to pursue further action you have documentation.

- Don’t Gossip

Nothing weakens you or your case more than gossiping. Keep your complaints professional and follow the chain of command.

- Evaluate

Depending on how issues are handled and resolved in your organization you may have to determine if staying in this environment is the best choice for you.

Every teacher or choreographer you encounter won’t be your absolute favorite. But chances are good that if you handle the situation professionally, most disputes can be resolved and you will gain the respect of those you work with.

If you determine that the situation is indeed unpleasant but tolerable, try to learn something from it. Grow from it and take mental notes to remember when you become a teacher. Hopefully you will never make your students feel this way.

If it truly is a situation that continues to wreak havoc on you, your self-esteem and your love for dance, or if it becomes physically abusive it’s ok to walk away. It’s ok to walk away even if you thought it was going to be your most amazing dance opportunity to date.

Accept that it wasn’t and begin the process of finding the place and people who are the right fit for you. It’s out there and your next favorite dance teacher or choreographer is waiting for you to step into his or her studio.

Stacy West is the Executive and Artistic Director of the St. Louis based MADCO (Modern American Dance Company), a 40-year old professional contemporary dance company that reaches over 30,000 people annually.

Photo credit : uhuru1701 via VisualHunt.com / CC BY-SA

Photo credit: grey_barklay via Visualhunt.com / CC BY-NC-ND