My entire life I’ve been told that I was going to have to work harder than anyone else to become a professional dancer. I’m only 4’11” and as I got older, my height became something I hated and it began to make me hate myself.

One year, I was told to lose weight by my teachers. This left me completely lost and devastated, but then I found Jess.

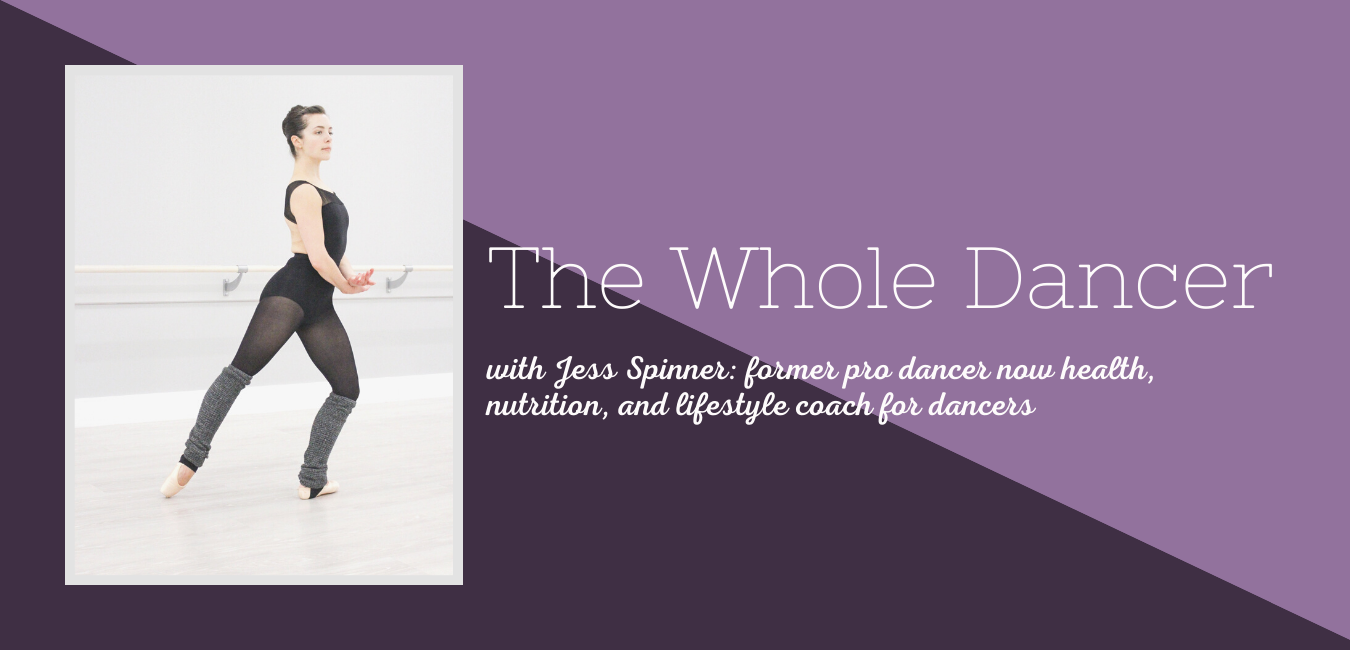

I remember one of my friends told me about the free webinars and how great an opportunity they are to learn tips and tricks from a former professional dancer, so I decided to sign up. I was completely hooked and at the end when Jess talked about The Whole Dancer Program, I immediately asked my mom if I could sign up.

Being a part of The Whole Dancer Program for two rounds has been absolutely amazing! I have learned so much from Jess, not only about how to be a better dancer but also how to become a better person.

This past year has been extremely difficult for me because as a high school senior I was dealing with the question of how to move forward after graduation. I was torn between going to college for dance (which would have made my parents happy) or auditioning for traineeships (which is what I really wanted to do).

I emailed Jess throughout the program and she gave me advice on basically everything and would get back to me so soon! My all time goal was to become a trainee with the Nashville Ballet, because I had been there for a couple of summers and fell in love with the environment.

Jess helped me keep a level head when it came to auditions and my mindset while waiting to hear if I had gotten in. When I found out I was accepted into the Nashville Ballet Professional Training Program for the 2016-2017 season, I immediately emailed Jess to let her know.

Without this program, I wouldn’t know as much as I do know about food and nutrition, stress management, organizing my goals, and how to properly cross train.

Because of Jess, I feel more comfortable in my own skin, and my height doesn’t bother me as much anymore.

I recommend this program to all dancers, even if they aren’t struggling and no matter where they are in their training!

Abby Zinsser trained at the Richmond Ballet. She is headed to Nashville to pursue her dream of a traineeship with the Nashville Ballet. Abby is a founding member of The Whole Dancer Program and took part in the program twice!