Diet for Dancers with Natasha Sheehan

The question of proper diet for dancers comes up quite often. What exactly should you be eating? The answer is unfortunately quite complex as the same foods do not work for all dancers.

One way to learn from other dancers is to hear how they’ve discovered their own best eating plans. Don’t copy what they’re doing but find out how they got there. Natasha Sheehan is a great example of a dancer who got here in a healthful and smart way. She has some smart food tips that can help you start on a path towards healthier eating.

She didn’t simply start eating how she thought she should eat. She read books and researched healthy eating for athletes. She also consulted with her doctors and took their advice into account.

In addition to the external research and gathering of advice, it’s important to listen to your body and follow its cues. Make it a goal to become an expert on your body.

Don’t ignore digestive disturbances or discomfort. If you’re constipated or experiencing painful cramping or diarrhea, these signs are likely connected to what you’re eating. If you’re feeling sluggish or tired, this could have to do with your food or beverage choices – caffeinated or sugary beverages will lead to spikes and crashes in energy.

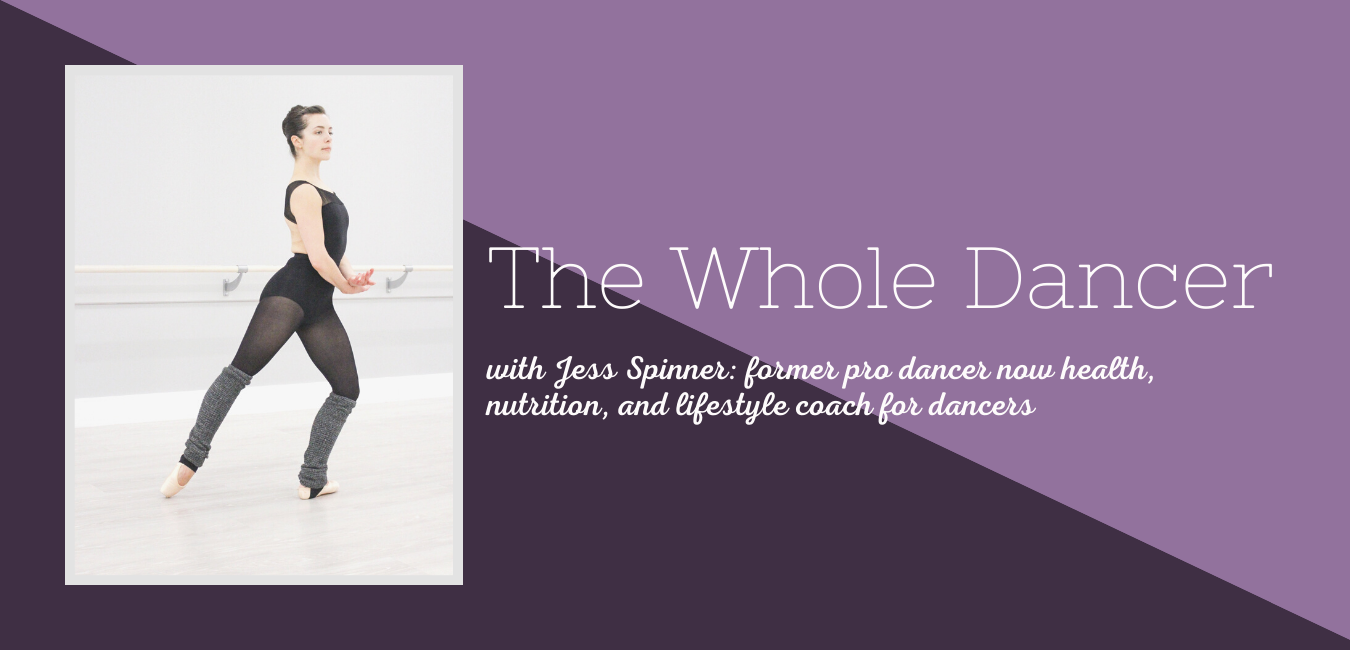

During my interview with Natasha Sheehan she shares the process she went through to find the best eating plan for her needs. At The Whole Dancer, it’s one of my goals to support you in finding the eating plan and balanced mindset around food that will get you to your personal best body.

That’s where The Dancer’s Best Body Program comes in – it’s enrolling this month for a limited time! To get the details and to join the wait list (as limited spaces are available) click here.

Have thoughts on Natasha’s approach to healthy eating or how you can get there yourself? Comment below or reach out by email : jess@thewholedancer.com

Photo of Natasha by Erik Tomasson

Pingback:It doesn't matter "What she eats in a day" - The Whole Dancer